I've had success with my Cast handgun loads and figured I'd try some things for a Browning BAR in .270. Wow the Manuals I have the Load Data Suck, and are inconsistent. Very few with OAL's and powder charge inconsistencies. Ok I'd appreciate anything you all could share to give me an Idea based on your experiences with the .270, and the Components I have. Any Ideas which way you'd start? Or a different Powder and Start. Not Looking for your specific, unless you just want to share. But Powders that maybe you tried that didn't perform as well as expected. Or what powder worked better. Maybe I need better books for my Rifle Loads? Or not even Try Loading Cast for this Semi Auto .270. Maybe go to a Heavier Boolit.

Thanks In Advance

Browning BAR Mark I .270 caliber

Universal neck expander

Brass Win, Fed, Frontier Rem. All brass has been FL sized, also have a Neck Sizer

Primers Win Large Rifle and CCI 200 Large Rifle.

My Boolits should be Lyman#2 hardness (or Close)

Lee Mold # C277-135rf, average wt 136.2gr, Powder Coated, Gas Checked, sized at .278

My OAL. Inserting dummy cartridges into the chamber, appear to hit the lands at a Length of 3.22 so I'm figuring 3.12 or there about.

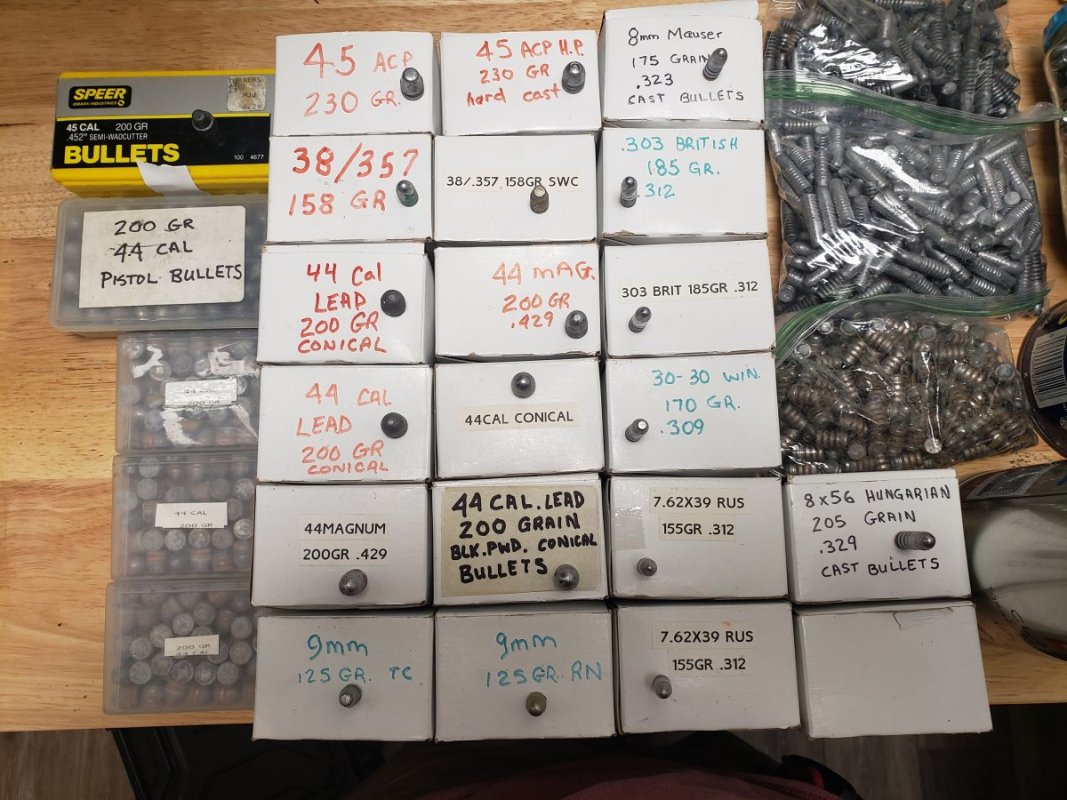

Powders Listed are Powders I have on hand.

Varget

4064

4198

4227

4350

3031

2400

Herco

Unique

Lyman's Cast Manual #3 *** the most useful so Far

mold #280412- 136gr

OAL 3.095

Unique Start 11.5 Max 14.8

Herco 12.0 15.0

IMR 3031 29.2 40.0

Lyman #47 Nadda

Lyman #48 Nadda

Lyman #44

Mold #280412- 136gr

No OAL

Unique Start 8.0 Max 12 **Big Difference?** Compared to above listed Lyman#3

No Herco Listed

No IMR3031 Listed

2400 15.0 23.0

IMR4227 15.0 25.0

IMR4198 20.0 28.0

Thanks In Advance

Browning BAR Mark I .270 caliber

Universal neck expander

Brass Win, Fed, Frontier Rem. All brass has been FL sized, also have a Neck Sizer

Primers Win Large Rifle and CCI 200 Large Rifle.

My Boolits should be Lyman#2 hardness (or Close)

Lee Mold # C277-135rf, average wt 136.2gr, Powder Coated, Gas Checked, sized at .278

My OAL. Inserting dummy cartridges into the chamber, appear to hit the lands at a Length of 3.22 so I'm figuring 3.12 or there about.

Powders Listed are Powders I have on hand.

Varget

4064

4198

4227

4350

3031

2400

Herco

Unique

Lyman's Cast Manual #3 *** the most useful so Far

mold #280412- 136gr

OAL 3.095

Unique Start 11.5 Max 14.8

Herco 12.0 15.0

IMR 3031 29.2 40.0

Lyman #47 Nadda

Lyman #48 Nadda

Lyman #44

Mold #280412- 136gr

No OAL

Unique Start 8.0 Max 12 **Big Difference?** Compared to above listed Lyman#3

No Herco Listed

No IMR3031 Listed

2400 15.0 23.0

IMR4227 15.0 25.0

IMR4198 20.0 28.0

Last edited: