Hey folks,

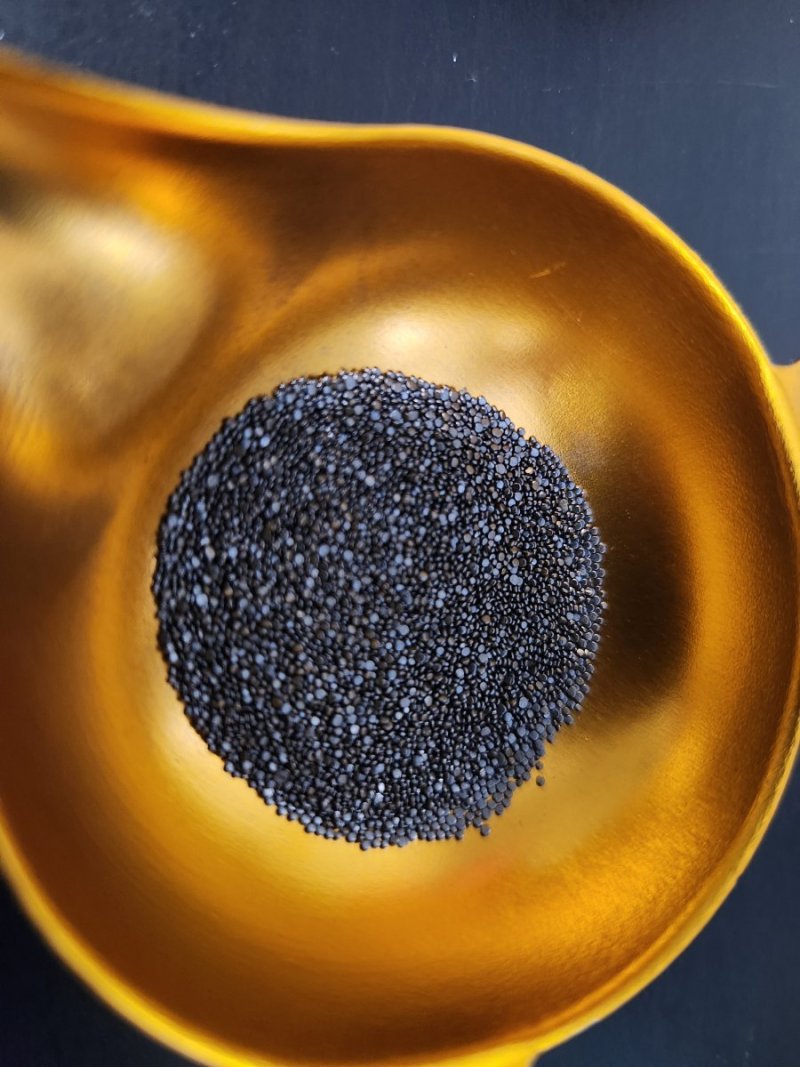

Having issues with my lee pro 1000( there's a shocker...) This thing has been a bitch to get working right and keep it that way. Loaded about 1000 or so rounds but was loading the other night and the powder hopper position on the press ate the **** out of the mouth of one of my cases. No lingers drops powder, maybe .2gr on the disk that was preciously measuring 3.4 every pull.

Yes hopper is on the right way with disk correctly aligned. Hopper lifts as normal which used to deposit powder. Hopper arm appears to be actuating correctly.

I'm stumped, any guesses? Thinking inside the powder die there may have been something I boogered up?

Having issues with my lee pro 1000( there's a shocker...) This thing has been a bitch to get working right and keep it that way. Loaded about 1000 or so rounds but was loading the other night and the powder hopper position on the press ate the **** out of the mouth of one of my cases. No lingers drops powder, maybe .2gr on the disk that was preciously measuring 3.4 every pull.

Yes hopper is on the right way with disk correctly aligned. Hopper lifts as normal which used to deposit powder. Hopper arm appears to be actuating correctly.

I'm stumped, any guesses? Thinking inside the powder die there may have been something I boogered up?