Hey guys, recently got an AAC Tirant 9 and I've been reading up on proper usage and all but just looking for some real-world tips and suggestions. Smart asses need not reply - I'm looking for real, actual, helpful information here.

So my current setup is the can with both the 1/2x28" and the 13x1LH pistons just in case I end up with that thread pitch. I do have the piston spacer so I can use it on fixed barrels as well. Right now I am also using it to shoot 300BLK (subsonic only and a barrel threaded 1/2x28" so no adapter needed) and .22LR but eventually plan to get a dedicated 22 can so I don't keep pumping loose lead into this one.

Here's my questions and kind of where I want this thread to go:

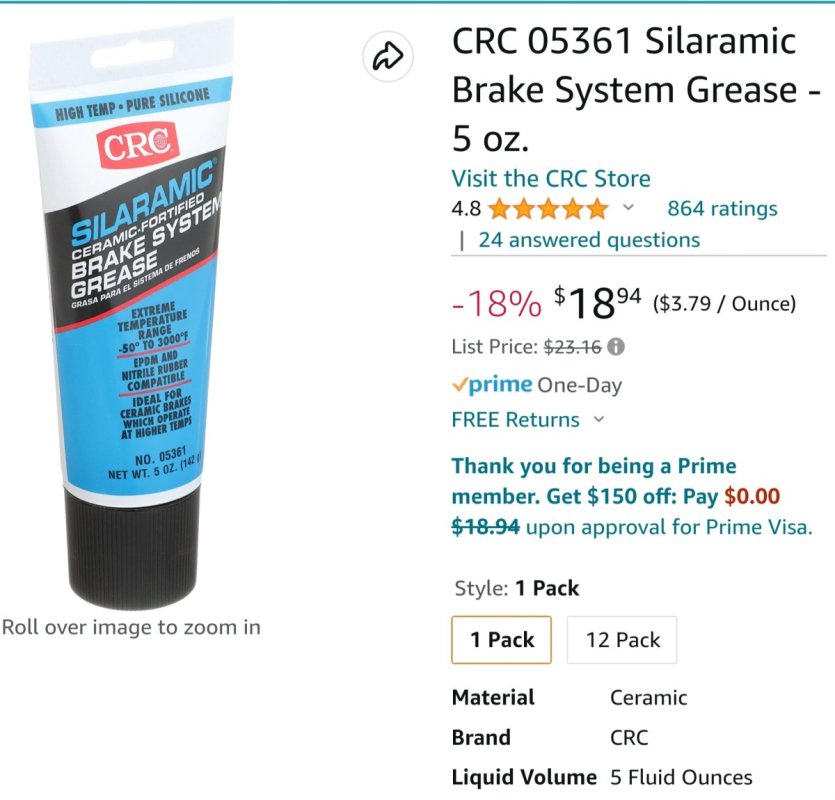

1. Keeping it tight: I've noticed it sometimes becomes a little loose after shooting a couple magazines, especially from a floating barrel like a Glock. Have you guys ever tried using a lock washer or something that would put tension against the can to keep it from backing off? Does it work? I've read to just tighten the hell out of it with no grease or anything on the threads but that makes it a little more difficult to swap hosts back and forth in the range, especially when its hot as hell. Which leads me to question 2...

2. Hot cans: Do you guys just carry gloves with you to the range? Just sit it down until it cools off? Have a wrap or cover that goes around the can? What works best for you? Ideally I'd like to be able to shoot a couple magazines from one gun, take the can off, put it on another host, shoot a couple mags through it, etc. I'm the type of guy that likes to take 5-6 guns with me to the range and put around 100 rounds through each while I'm there. Just trying to find a quicker way to transition from one gun to the next. Gloves seem like the most obvious way to go but shooting gloves are thin and don't help, thick heat protection gloves (like welding gloves) are way too thick to shoot with...have you found a balance in-between?

3. Cleaning: Oh yes, the question that always comes up. My baffles are aluminum with a steel blast baffle, so I know I can't just soak them. Is it ok to use a bore foam? Does it help? Dumb question, but are you guys that are using bore foam just spraying it into the can or taking the baffles out and coating them outside the can? If you're spraying it while they're in the can, are you taking them out afterwards and cleaning with a brush, just spraying them off with another product and/or water, or just walking away and not touching it afterwards at all? What else works for you? Do you even clean it at all?? I've read where some never do and claim that you don't need to.

4. Coating: So I don't even know the legalities of this one but have any of you ever coated and/or painted your cans? I know the serial number would have to be taped off first, but I was wondering if a high-heat undercoating type of material would make it easier to tighten / loosen the can as it gives better traction. I've read that plastic-dip can be applied to value covers and exhaust tips without a problem but not sure if it would stand up to the suppressor temps of shooting 22, 9, and 300blk. Thoughts?

So my current setup is the can with both the 1/2x28" and the 13x1LH pistons just in case I end up with that thread pitch. I do have the piston spacer so I can use it on fixed barrels as well. Right now I am also using it to shoot 300BLK (subsonic only and a barrel threaded 1/2x28" so no adapter needed) and .22LR but eventually plan to get a dedicated 22 can so I don't keep pumping loose lead into this one.

Here's my questions and kind of where I want this thread to go:

1. Keeping it tight: I've noticed it sometimes becomes a little loose after shooting a couple magazines, especially from a floating barrel like a Glock. Have you guys ever tried using a lock washer or something that would put tension against the can to keep it from backing off? Does it work? I've read to just tighten the hell out of it with no grease or anything on the threads but that makes it a little more difficult to swap hosts back and forth in the range, especially when its hot as hell. Which leads me to question 2...

2. Hot cans: Do you guys just carry gloves with you to the range? Just sit it down until it cools off? Have a wrap or cover that goes around the can? What works best for you? Ideally I'd like to be able to shoot a couple magazines from one gun, take the can off, put it on another host, shoot a couple mags through it, etc. I'm the type of guy that likes to take 5-6 guns with me to the range and put around 100 rounds through each while I'm there. Just trying to find a quicker way to transition from one gun to the next. Gloves seem like the most obvious way to go but shooting gloves are thin and don't help, thick heat protection gloves (like welding gloves) are way too thick to shoot with...have you found a balance in-between?

3. Cleaning: Oh yes, the question that always comes up. My baffles are aluminum with a steel blast baffle, so I know I can't just soak them. Is it ok to use a bore foam? Does it help? Dumb question, but are you guys that are using bore foam just spraying it into the can or taking the baffles out and coating them outside the can? If you're spraying it while they're in the can, are you taking them out afterwards and cleaning with a brush, just spraying them off with another product and/or water, or just walking away and not touching it afterwards at all? What else works for you? Do you even clean it at all?? I've read where some never do and claim that you don't need to.

4. Coating: So I don't even know the legalities of this one but have any of you ever coated and/or painted your cans? I know the serial number would have to be taped off first, but I was wondering if a high-heat undercoating type of material would make it easier to tighten / loosen the can as it gives better traction. I've read that plastic-dip can be applied to value covers and exhaust tips without a problem but not sure if it would stand up to the suppressor temps of shooting 22, 9, and 300blk. Thoughts?

Last edited: