if I remember correctly you have to "pickle" stainless". It uses a mild acid and then color the steel. It's been a long time since I came across that, do some googling to be sure.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

First attempt at force-aging a bladeblade

- Thread starter synspeed

- Start date

Ferric chloride will darken stainless to a light grey. Will look darker until you buff with 000 or 0000 steel wool as was mentioned above. I use 50/50 ferric and white vinegar, other guys cut 50/50 with distilled water.

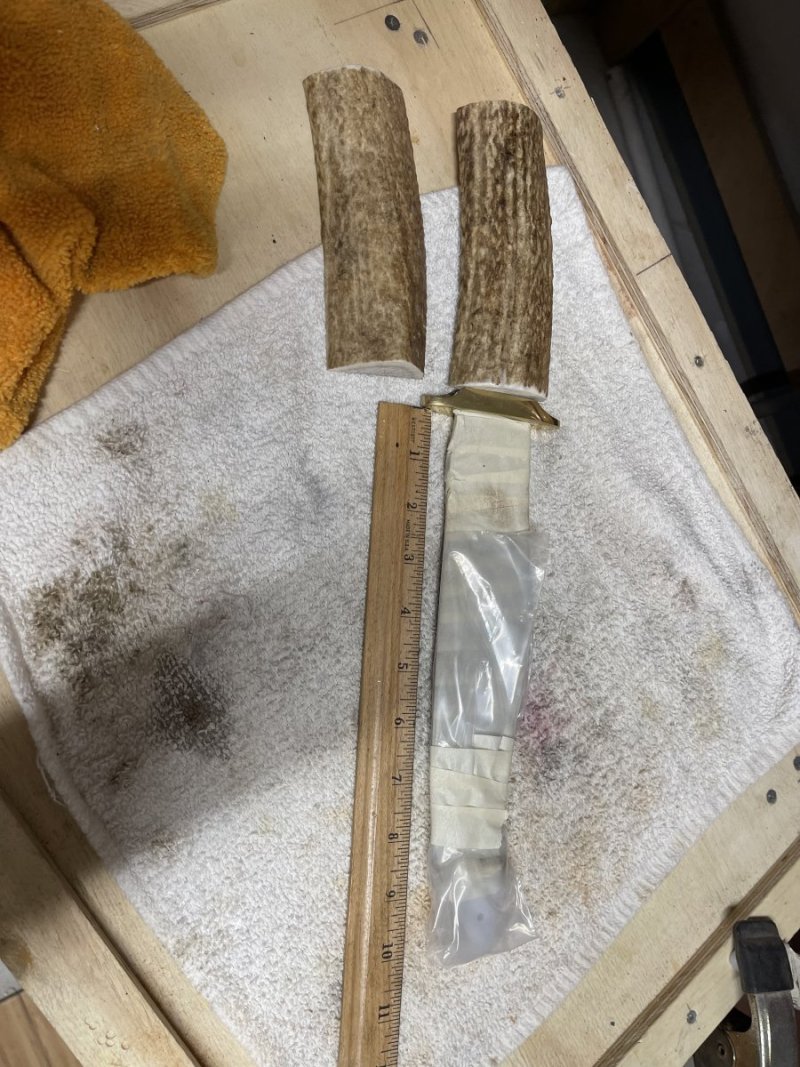

Synspeed is that O-1? I did two blades this weekend and I'm so used to stainless that I soaked the O-1 a bit long, I had to make a couple of passes with a 220 belt and then etch again. I'll post pics if I remember once I finish the handle. I etch after the handles are on and done because once you glue up you will remove all the etch when you grind the handle flush with the steel. Of course a q-tip will handle those areas if you worry about the etchant coloring the handle...

Synspeed is that O-1? I did two blades this weekend and I'm so used to stainless that I soaked the O-1 a bit long, I had to make a couple of passes with a 220 belt and then etch again. I'll post pics if I remember once I finish the handle. I etch after the handles are on and done because once you glue up you will remove all the etch when you grind the handle flush with the steel. Of course a q-tip will handle those areas if you worry about the etchant coloring the handle...

This one is actually 1095. I'm making most of my newer blades from O1 though.Ferric chloride will darken stainless to a light grey. Will look darker until you buff with 000 or 0000 steel wool as was mentioned above. I use 50/50 ferric and white vinegar, other guys cut 50/50 with distilled water.

Synspeed is that O-1? I did two blades this weekend and I'm so used to stainless that I soaked the O-1 a bit long, I had to make a couple of passes with a 220 belt and then etch again. I'll post pics if I remember once I finish the handle. I etch after the handles are on and done because once you glue up you will remove all the etch when you grind the handle flush with the steel. Of course a q-tip will handle those areas if you worry about the etchant coloring the handle...