Ive got three top quality molds fs right now. But as previously stated, you may want to start witht the Lee aluminum molds to learn how to cast first. They are easy to cast with and not as expensive if you mess up.

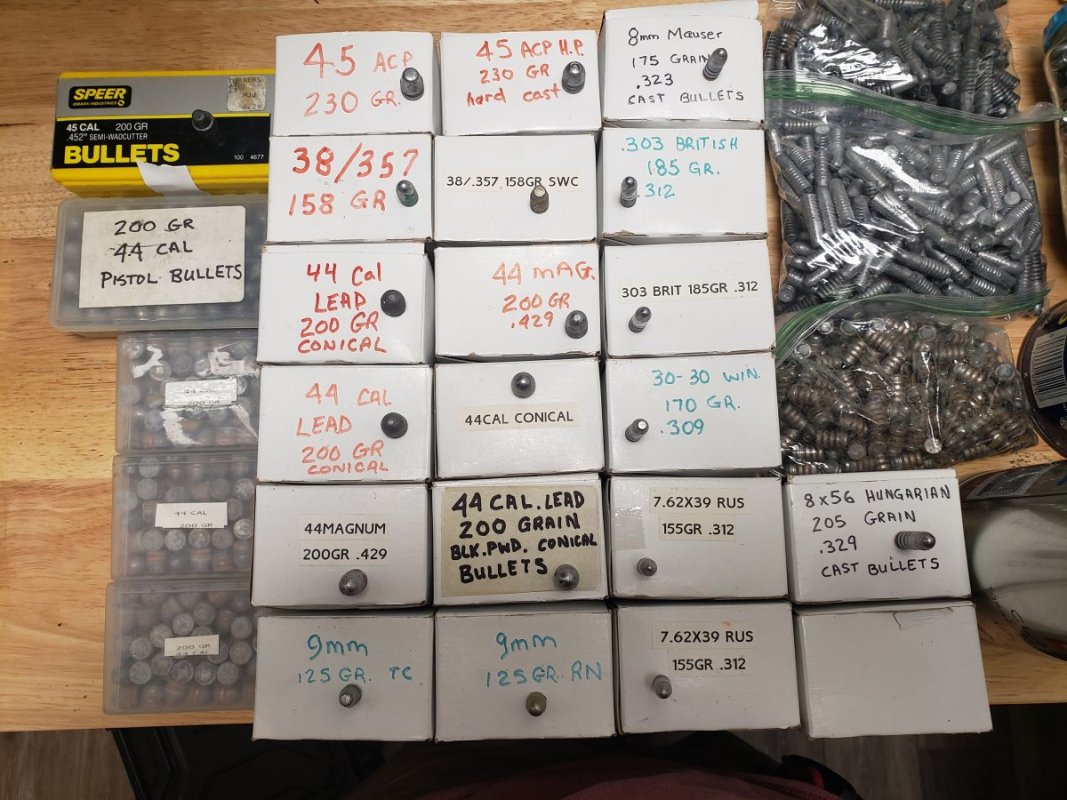

The above advice about collecting stuff as you can now is good advice.

The above advice about collecting stuff as you can now is good advice.