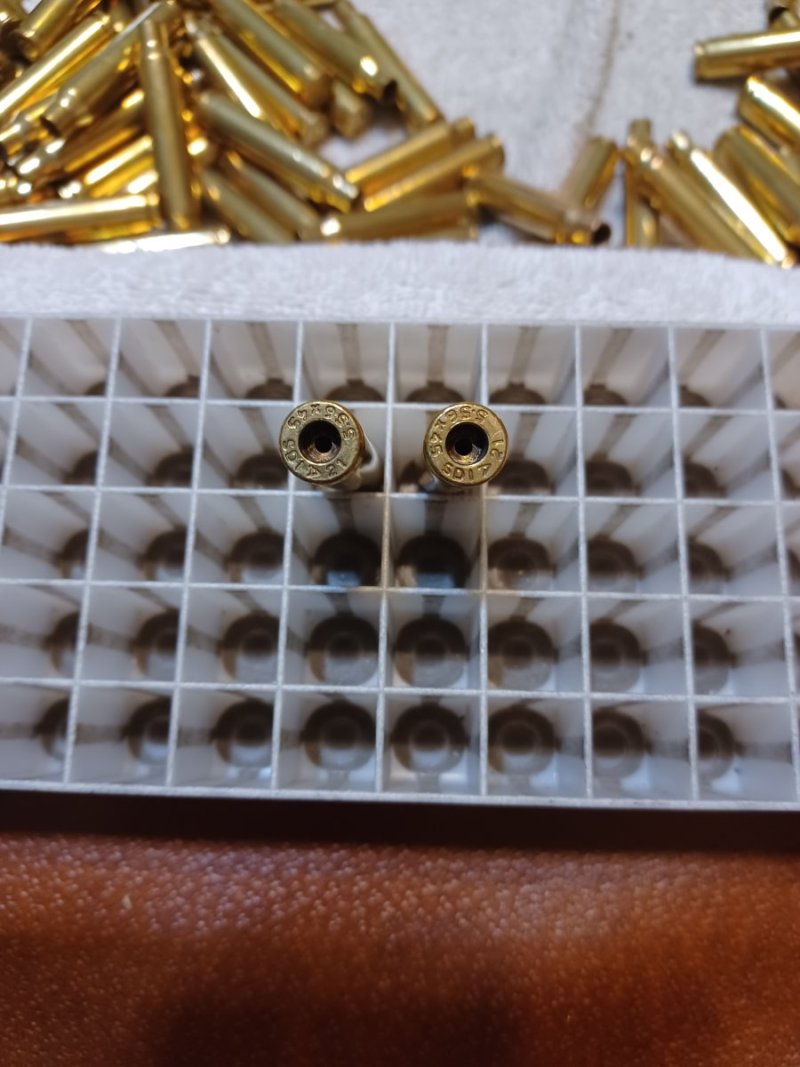

Like some other posters here, I am rethinking loading .223 at the current prices. I'm saving myself maybe-- MAYBE $8/hour for my time. If primers and powder get cheaper, or ammo goes up-- reloading makes more sense. If I can't get more than 3 loads out of the brass due to loss, I'm probably not saving anything at all.

I feel the same way about 9mm... at the moment, it's probably not worth reloading. .45 still is, for sure.

Wolf Gold... But even Federal American Eagle is getting reasonable. (Palmetto, etc.)

If you are willing to shoot Wolf steel-cased, there's no way you can beat that reloading.

I feel the same way about 9mm... at the moment, it's probably not worth reloading. .45 still is, for sure.

Wolf Gold... But even Federal American Eagle is getting reasonable. (Palmetto, etc.)

If you are willing to shoot Wolf steel-cased, there's no way you can beat that reloading.