so who here uses powder coat on their cast bullets?

anyone have a link to a good summary of how it's done and the process? I've been looking around castboolits and there's almost too much info there, and it's hard to find with some threads being hundreds of pages long. TL;DR

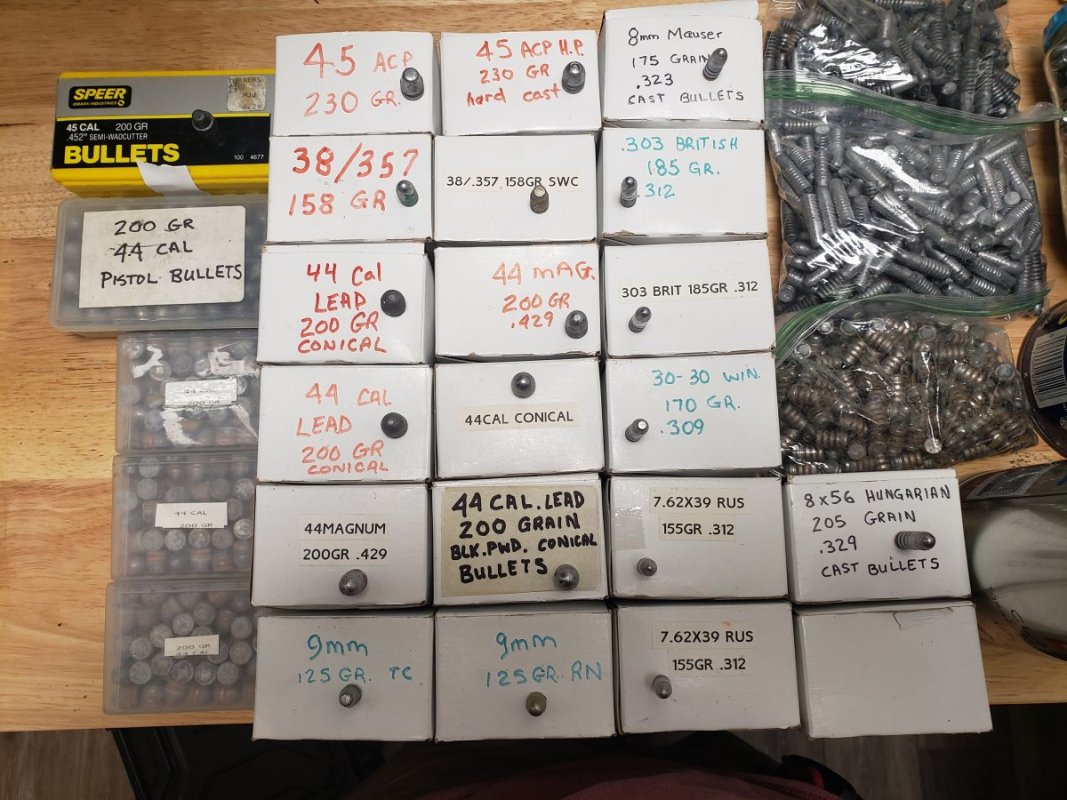

mainly considering 44mag, 300AACblackout, and possibly 6.8spc...

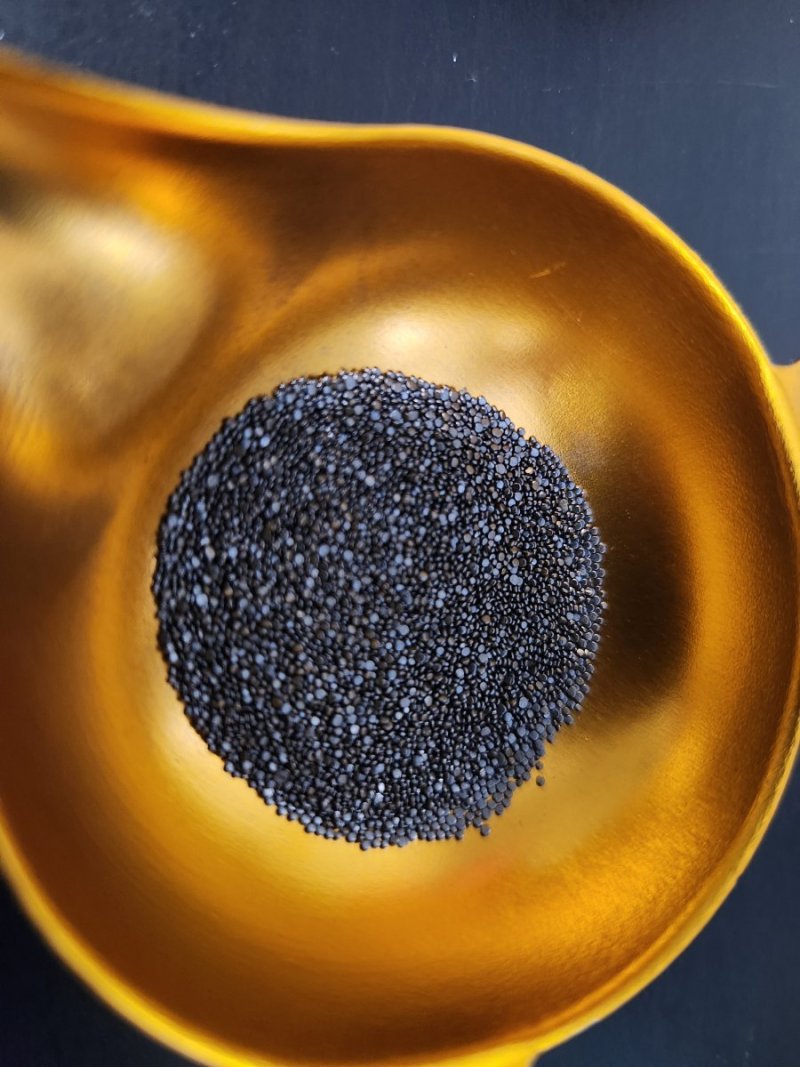

I've seen some folks that just tumble in dry powder, sift and dump on silicone cookie sheet, heat and size. Others do many steps, stand up each one individually, use powder guns, etc. etc.

what works for you?

anyone have a link to a good summary of how it's done and the process? I've been looking around castboolits and there's almost too much info there, and it's hard to find with some threads being hundreds of pages long. TL;DR

mainly considering 44mag, 300AACblackout, and possibly 6.8spc...

I've seen some folks that just tumble in dry powder, sift and dump on silicone cookie sheet, heat and size. Others do many steps, stand up each one individually, use powder guns, etc. etc.

what works for you?