Price? and waiting to see final product

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

ODT Gun Show & Swap Meet - May 4, 2024! - Click here for info

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

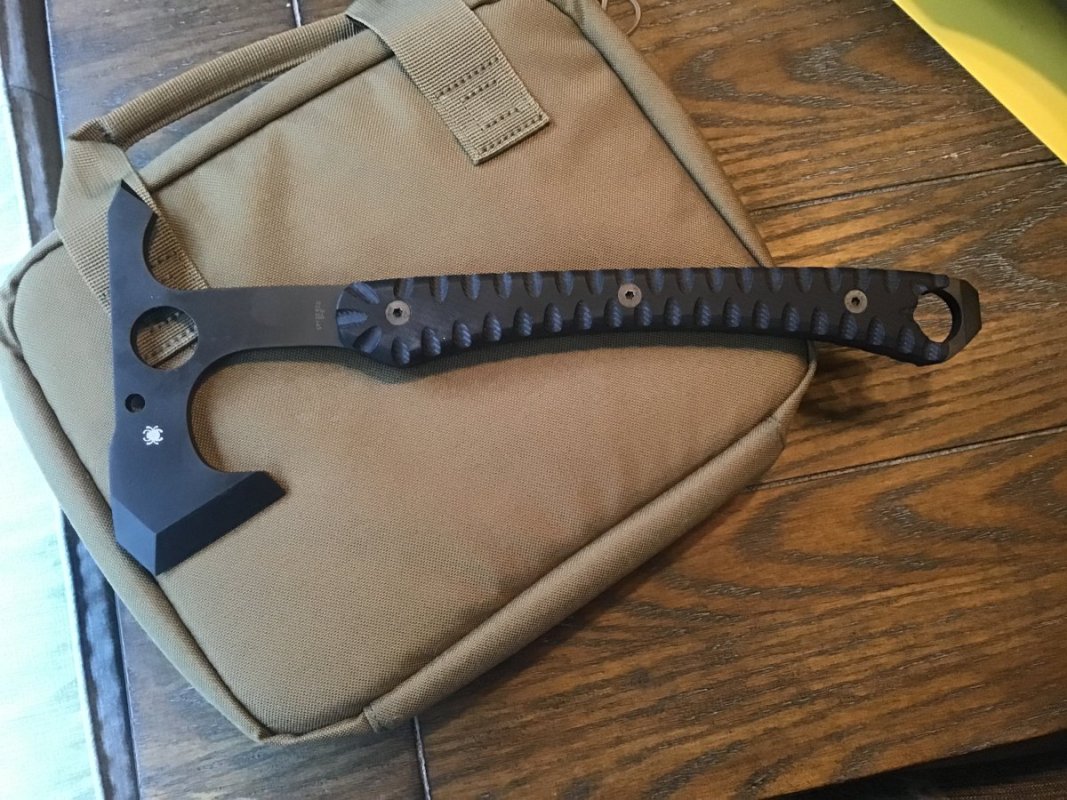

Tomahawk prototype - feedback welcome

- Thread starter blackplague14

- Start date

I like it a lot. Personally I would prefer about 3 to 3 1/2 inch cutting edge and a pointed beard. I really think the spike design is unique, looks good, and very practical. I'd like to have one, especially if it was significantly cheaper than say an RMJ or Winkler.

Thanks for all the suggestions!

Dial1911: In the other thread, you had some concerns about the spike. I will probably be making a few that come down straight on the back. Basically cutting off the spike before the hawk gets heat treated. That will make for a flat hammering surface for tent stakes etc. Secondly, I am pretty set on the handle design matching our pry bars, so I can have one type of G10 handle made that will fit both tools. Handle scales will probably be an additional purchased item, with the hawk coming with a paracord wrap handle.

woodstock: I'm guessing that we will have some ready within 6 months, maybe even a few by Blade Show in June. I don't have a price point yet, as I haven't decided on which type of steel or been given a price on the laser cut.

tellico426: I've seen that Gerber tool and it is cool. I think it is more of a demolition tool than what I am shooting for with this hawk. I'm kind of gearing it towards a light weight, versatile chopping/cutting blade.

sw0596: What would be the benefits of the smaller cutting edge and pointed beard? I went with the 4" cutting edge simply because of my personal preference. My daily carry knife is a 4". I did a flat point on the beard, thinking that it would be one less thing for me to hurt myself with while camping.. I'm guessing the smaller head and pointed beard would be more of a fighting hawk?

GA BOY: I'm hoping the price point will be similar to the CRKT hawks, but again, I haven't sourced materials yet.

dennis: I think that I am going to incorporate a cord cutter into the sheath design. Cut a 1/4" slot between two rivets at the blade edge. That would allow you to cut cordage while the hawk was still safely in it's sheath on your belt.

My friend at work who does our computer stuff is going to be on vacation next week, so I am hoping to get him to do a few simple changes to the design today, so that I can cut out an updated prototype. Then, I was up a couple of hours in the middle of the night thinking about the sheath design.

Again, thanks for all the suggestions and keep them coming!

Jon

Dial1911: In the other thread, you had some concerns about the spike. I will probably be making a few that come down straight on the back. Basically cutting off the spike before the hawk gets heat treated. That will make for a flat hammering surface for tent stakes etc. Secondly, I am pretty set on the handle design matching our pry bars, so I can have one type of G10 handle made that will fit both tools. Handle scales will probably be an additional purchased item, with the hawk coming with a paracord wrap handle.

woodstock: I'm guessing that we will have some ready within 6 months, maybe even a few by Blade Show in June. I don't have a price point yet, as I haven't decided on which type of steel or been given a price on the laser cut.

tellico426: I've seen that Gerber tool and it is cool. I think it is more of a demolition tool than what I am shooting for with this hawk. I'm kind of gearing it towards a light weight, versatile chopping/cutting blade.

sw0596: What would be the benefits of the smaller cutting edge and pointed beard? I went with the 4" cutting edge simply because of my personal preference. My daily carry knife is a 4". I did a flat point on the beard, thinking that it would be one less thing for me to hurt myself with while camping.. I'm guessing the smaller head and pointed beard would be more of a fighting hawk?

GA BOY: I'm hoping the price point will be similar to the CRKT hawks, but again, I haven't sourced materials yet.

dennis: I think that I am going to incorporate a cord cutter into the sheath design. Cut a 1/4" slot between two rivets at the blade edge. That would allow you to cut cordage while the hawk was still safely in it's sheath on your belt.

My friend at work who does our computer stuff is going to be on vacation next week, so I am hoping to get him to do a few simple changes to the design today, so that I can cut out an updated prototype. Then, I was up a couple of hours in the middle of the night thinking about the sheath design.

Again, thanks for all the suggestions and keep them coming!

Jon

Thanks for all the suggestions!

Dial1911: In the other thread, you had some concerns about the spike. I will probably be making a few that come down straight on the back. Basically cutting off the spike before the hawk gets heat treated. That will make for a flat hammering surface for tent stakes etc. Secondly, I am pretty set on the handle design matching our pry bars, so I can have one type of G10 handle made that will fit both tools. Handle scales will probably be an additional purchased item, with the hawk coming with a paracord wrap handle.

woodstock: I'm guessing that we will have some ready within 6 months, maybe even a few by Blade Show in June. I don't have a price point yet, as I haven't decided on which type of steel or been given a price on the laser cut.

tellico426: I've seen that Gerber tool and it is cool. I think it is more of a demolition tool than what I am shooting for with this hawk. I'm kind of gearing it towards a light weight, versatile chopping/cutting blade.

sw0596: What would be the benefits of the smaller cutting edge and pointed beard? I went with the 4" cutting edge simply because of my personal preference. My daily carry knife is a 4". I did a flat point on the beard, thinking that it would be one less thing for me to hurt myself with while camping.. I'm guessing the smaller head and pointed beard would be more of a fighting hawk?

GA BOY: I'm hoping the price point will be similar to the CRKT hawks, but again, I haven't sourced materials yet.

dennis: I think that I am going to incorporate a cord cutter into the sheath design. Cut a 1/4" slot between two rivets at the blade edge. That would allow you to cut cordage while the hawk was still safely in it's sheath on your belt.

My friend at work who does our computer stuff is going to be on vacation next week, so I am hoping to get him to do a few simple changes to the design today, so that I can cut out an updated prototype. Then, I was up a couple of hours in the middle of the night thinking about the sheath design.

Again, thanks for all the suggestions and keep them coming!

Jon

If you did that make sure to make me one I'll want one.

Looking good, brother! Keep us updated!

Keep us updated!

Keep us updated!

Keep us updated!Computer guy made some changes for me in the program, but I didn't get a chance to burn one out. I had to get home to my son's lacrosse game. I did get called in for work tomorrow, so I hope to get a chance to do it then. But I can't stay after work because my other son is testing for his black belt!

I'll post some pics up when I get the new prototype burned out and cleaned up.

I'll post some pics up when I get the new prototype burned out and cleaned up.

BP, as usual you have created another very cool and functional tool. I have no criticisms at all. I do kinda like the hammer backed head idea but if you did that could you put the chisel end pointing downward from the handle so it has all 3 (cut, hammer & chisel)

Attachments

Last edited:

Looks really good!