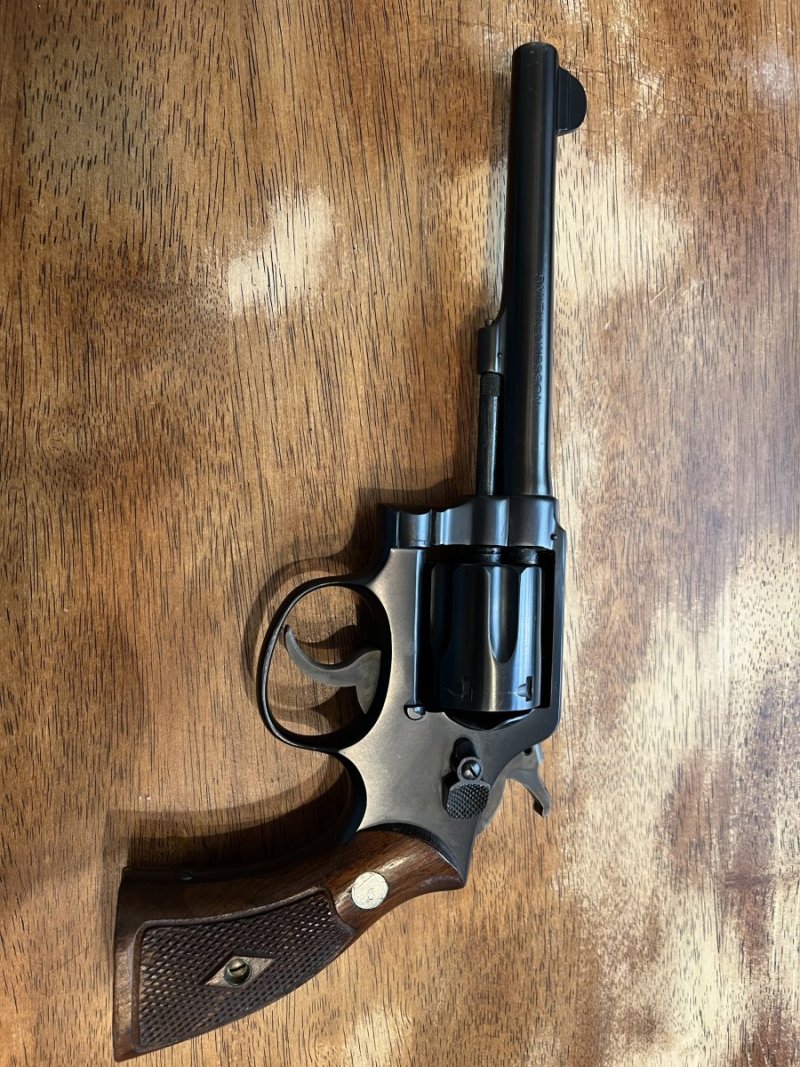

The 457 arrived at TruPrep/Kudzu Tactical today, so I picked her up.

Cleaned her, removed the magazine disconnect, and replaced the springs. I forgot how nice the triggers are on these 3rd Gen S&W's. The reset is better than the one on my P229 with the SRT.

Quite a bit of holster wear, but low mileage on the inside. Cleaned up very nicely.

I screwed up and ordered the wrong Trijicons, so they're headed back tomorrow for a swap. Some mags arrived, some are en route.

I'll start the project in about 1.5 weeks, when I'm back from vacation. Several slide modifications, stipple the front strap, maybe stipple the frame for a thumb rest, then off to Robar for NP3+ on frame, barrel, and internals. When she's back, the slide will head off for IonBond/DLC.

Cleaned her, removed the magazine disconnect, and replaced the springs. I forgot how nice the triggers are on these 3rd Gen S&W's. The reset is better than the one on my P229 with the SRT.

Quite a bit of holster wear, but low mileage on the inside. Cleaned up very nicely.

I screwed up and ordered the wrong Trijicons, so they're headed back tomorrow for a swap. Some mags arrived, some are en route.

I'll start the project in about 1.5 weeks, when I'm back from vacation. Several slide modifications, stipple the front strap, maybe stipple the frame for a thumb rest, then off to Robar for NP3+ on frame, barrel, and internals. When she's back, the slide will head off for IonBond/DLC.