cooking oil or olive oil is ok for quenching

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

ODT Gun Show & Swap Meet - May 4, 2024! - Click here for info

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Heat treat without a forge?

- Thread starter Laxguy59

- Start date

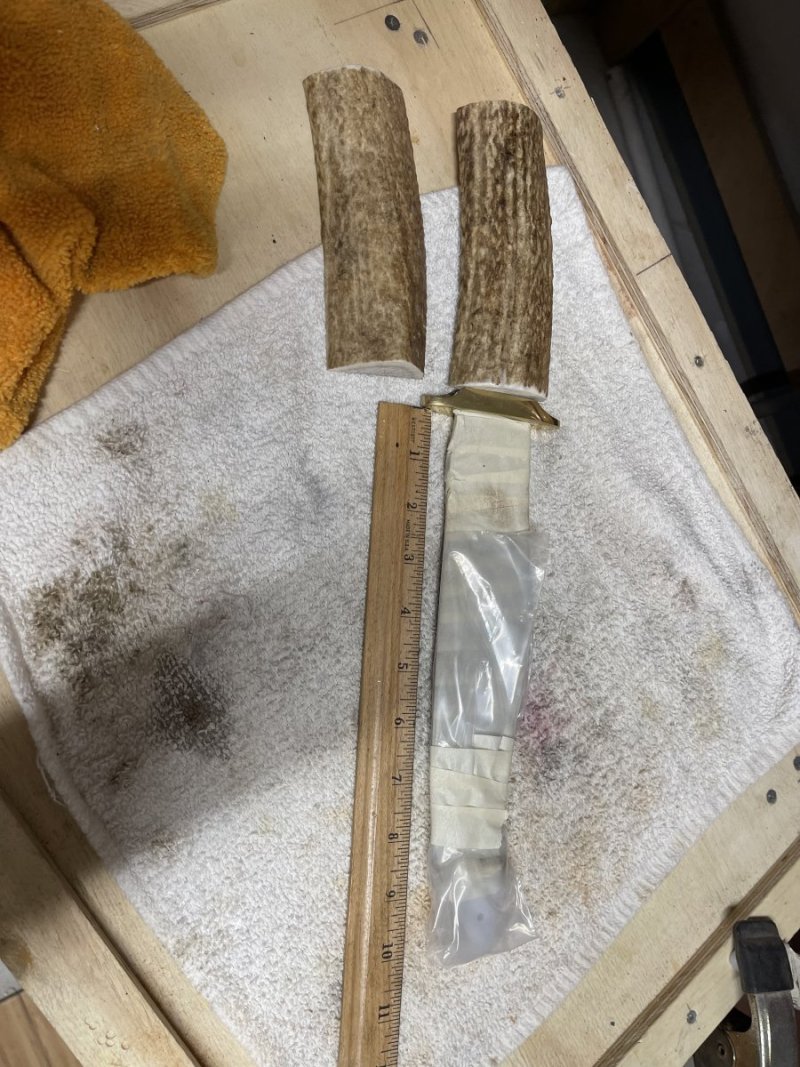

It's 6.5" from tip to tip.

I gotcha, you might want to use a heat treat oven. Non Liberal may have one.

Depends on the metal. Canola works good for most.

cooking oil or olive oil is ok for quenching

And used motor oil if you have any on hand.

I also know that there are companies out there that will heat treat a blade after you've formed it. Not terribly expensive. I'd have to go check the blade forums website to get names-

And used motor oil if you have any on hand-

I've used burnt motor oil mixed with water, kerosene, hydraulic fluid, WD-40 because of water content, water with dawn dish detergent etc, lol in an industrial setting. I was trying to think of something he may have at home for quenching.

If I am correct in thinking of what he has to be hardened, I would just contact Nonliberal or another machine shop that has a heat treat oven. It should be relatively cheap to heat treat a part and quench it.

I've used burnt motor oil mixed with water, kerosene, hydraulic fluid, WD-40 because of water content, water with dawn dish detergent etc, lol in an industrial setting. I was trying to think of something he may have at home for quenching.

If I am correct in thinking of what he has to be hardened, I would just contact Nonliberal or another machine shop that has a heat treat oven. It should be relatively cheap to heat treat a part and quench it.

This is my 2nd knife ever and honestly not nice enough to worry that much about it, I'm doing this one more so to work on shaping a decent handle.

This is my 2nd knife ever and honestly not nice enough to worry that much about it, I'm doing this one more so to work on shaping a decent handle.

Gotcha, in that case, I'd make a small brick structure, obtain desired temp, insert blade, according to metal alloy leave for X amount of time, then quench. I feel sure there is something online that would give you a guideline for the optimum temp according to the metal alloy to do what you are wanting to do.

Over the years, I have made several work knives from old files.

Don't use motor oil. To many toxins.

Heated canola is good for 5160.

How did you make the blade? Or did you buy a blank and shape/sharpen it now trying to heat treat it?

Heated canola is good for 5160.

How did you make the blade? Or did you buy a blank and shape/sharpen it now trying to heat treat it?

Don't use motor oil. To many toxins.

Heated canola is good for 5160.

How did you make the blade? Or did you buy a blank and shape/sharpen it now trying to heat treat it?

Cut it out of sheet steel from Home depot with a router.

Cut it out of sheet steel from Home depot with a router.

Huh? Soft metal?

Similar threads

- Replies

- 41

- Views

- 1K