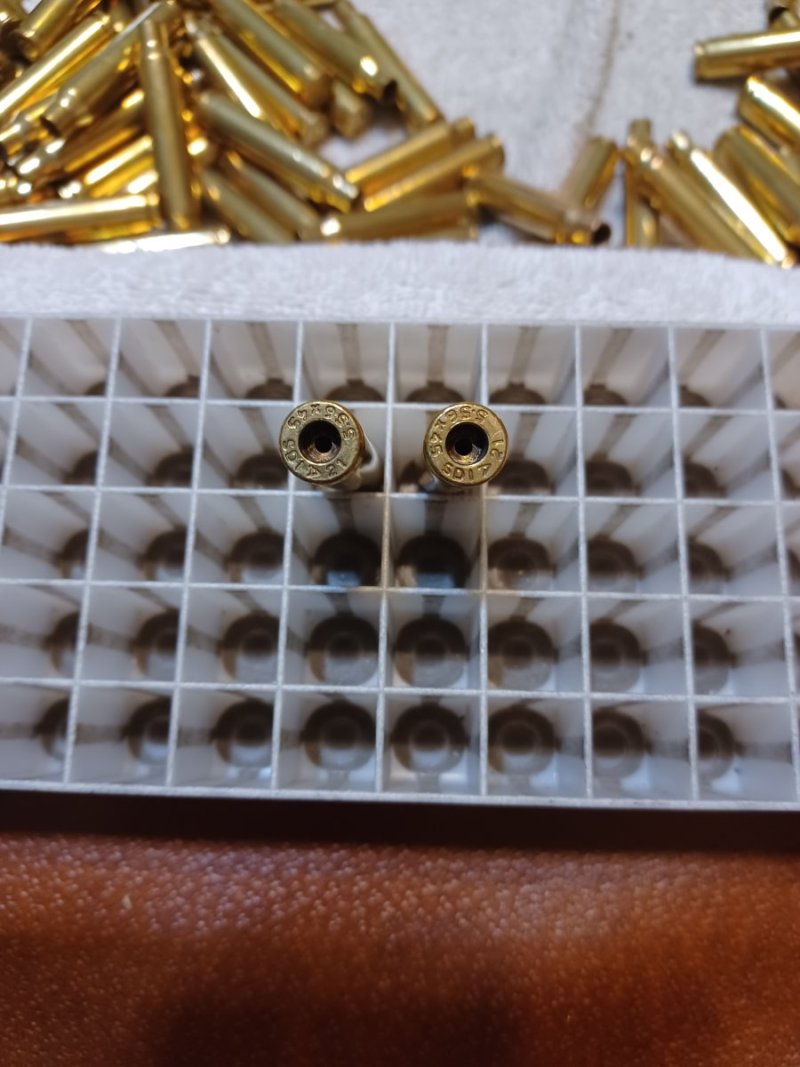

You need a trimmer if your going to be loading any type of bottleneck calibers.

Performance, but most importantly, safety makes it a necessity. Long cases not only

don't go into full battery reliably, but if they are forced closed, can and will drive

pressures literally through the roof. A long case can cause the bullet to be squeezed

much too tight when chambered.

I full length size all new brass and trim many new ones simply for uniformity, especially for precision

loads.

Yea, if loading for rifles, trimming is a necessary evil.

Performance, but most importantly, safety makes it a necessity. Long cases not only

don't go into full battery reliably, but if they are forced closed, can and will drive

pressures literally through the roof. A long case can cause the bullet to be squeezed

much too tight when chambered.

I full length size all new brass and trim many new ones simply for uniformity, especially for precision

loads.

Yea, if loading for rifles, trimming is a necessary evil.